Individually configurable

Assemble your machine exactly to your requirements.

An overview of the K 37’s key features.

15 “touchscreen with 3D graphics support.

Milling with multi-radius can be equipped in the base machine.

Machine is ready to work in six minutes thanks to its fast-heating pot.

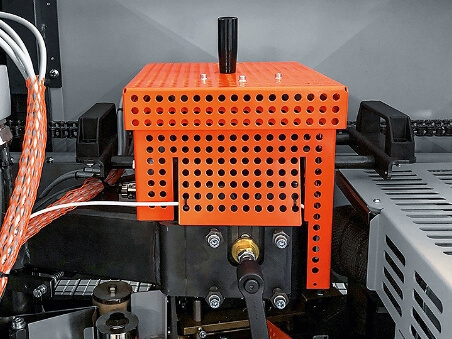

Airtronic

Three power advantages for the K 37.

Assemble your machine exactly to your requirements.

We guarantee that your production runs and that the calculation is correct..

A Hebrock is always an investment in the future.

The K 37 means edge banding at its best and sets standards in terms of multitasking and comfort. For example with the clear, easy-to-use 10" screen control. No wish remains unfulfilled and no order remains unprocessed. It is a model of throughput and service life - of course from A to Z made in Germany.

An Automatic Edge Banding Machine works by following a series of steps that deliver precise and consistent results. Here's a breakdown of how the Altendorf K 37 Automatic Edge Banding Machine works:

The Altendorf K 37 Automatic Edge Banding Machine is an investment that can revolutionize your woodworking production. The price of the K 37 varies depending on the specific features and customization options you choose. However, with Altendorf's reputation for quality and precision, you can be assured that every rupee invested in an Altendorf machine is well worth it. Contact us today to get a customized quote for your business needs and take the first step towards optimizing your woodworking operations.

Hebrock edge banding machines are suitable for almost every type of wood. Whether solid wood, chipboard, blockboard, MDF or multiplex - you can always rely on precise and clean edge processing (including finishing).

These HPL panels come in a variety of dimensions, thicknesses and surface varieties. With the help of Altendorf edgebanders, they can be efficiently and flexibly processed. Our machines are designed to handle a wide range of material dimensions. Pay attention to the particular technical profile.

Edge banding on plastics, for example on PP sandwich panels, is an important part of the craft. With Hebock edge banding machines, you also rely on productivity and flexibility during processing. And always offer your customers first-class quality.

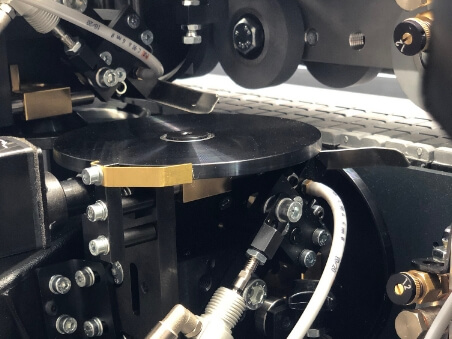

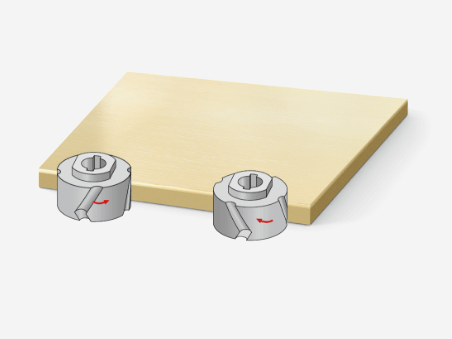

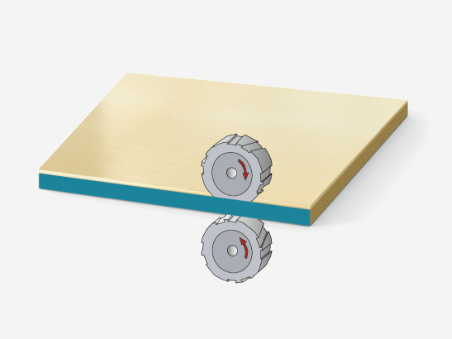

Pre-milling aggregate

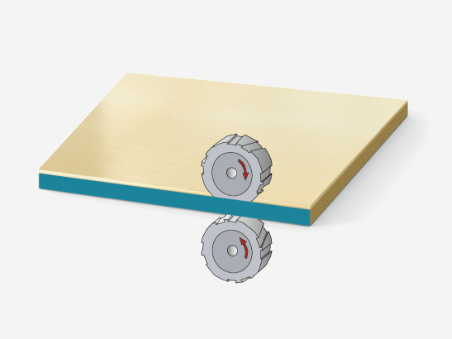

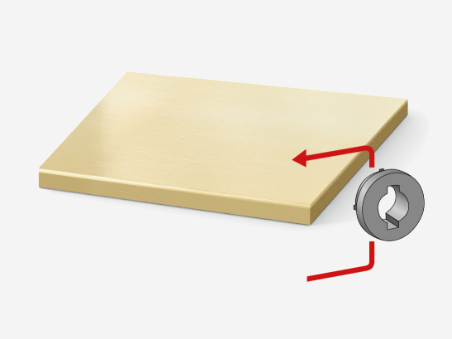

Trim saw

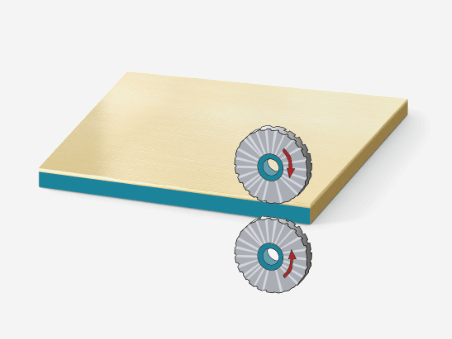

Top/bottom trimming

2. Top/bottom trimming (optional)

Corner rounding unit

Radius profile scraper

Surface scraper dual-tracing

Buffer unit

Grooving saw (side or from below)

| Max. edge thickness | 3 mm (optional up to 8 mm) |

| Min./max. workpiece thickness | 8 – 60 mm* |

| Min. Min. workpiece length | Approx. 200 mm* |

| Min. Min. workpiece width | Approx. 80 mm* |

| Feed speed | Approx. 15 m/min. |

| Ready to operate in | Approx. 6 min. |

| Max. power consumption | max. about 14.6 kW |

| Electrical connection | 400 V – 3 Ph – 50 Hz |

| Machine dimensions | 6000 x 1230 x 1430 mm (LxWxH) |

| Weight | Approx. 2,000 kg |

Airtronic

As with our machines, we also place the highest demands on our service.